Foam Waste: The Silent Killer.

Foam wastage after shaping is one of the most overlooked costs in surfboard production.

Every litre carved away during shaping represents not only money out the door but also contributes to pollution.

Reducing waste isn’t just an environmental responsibility — it’s a smart move for the bottom line.

Shape-Smart Design.

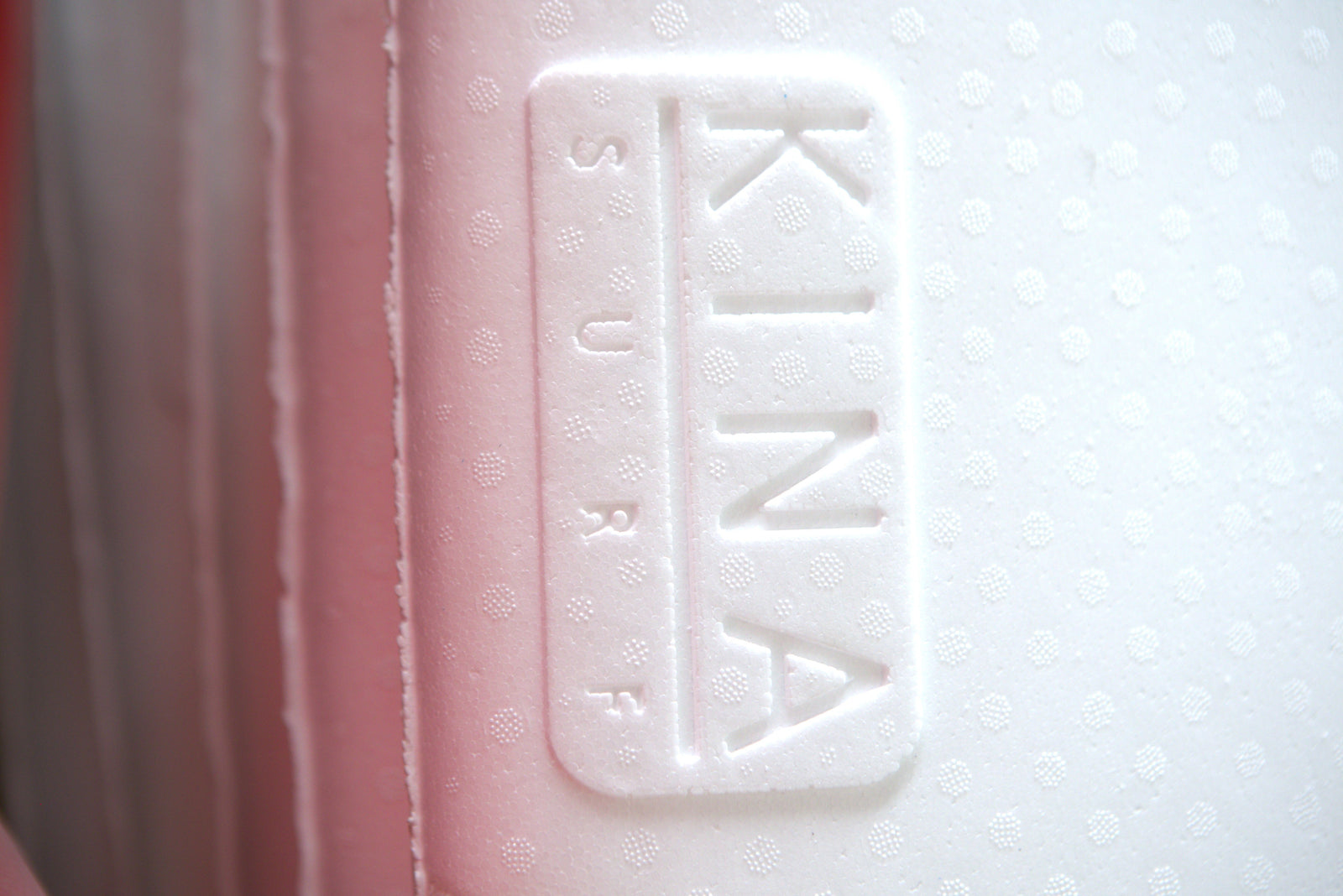

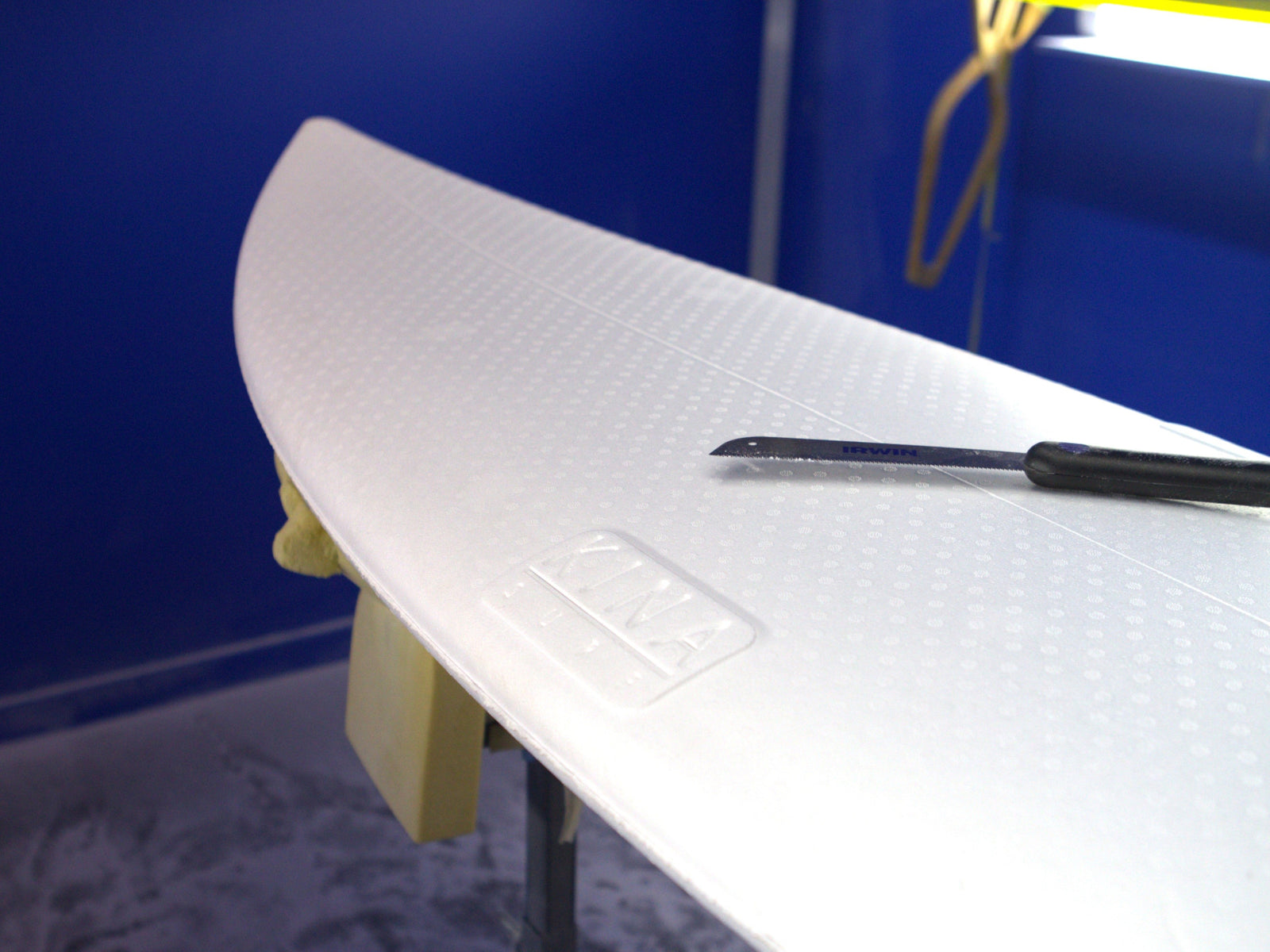

The Kinablank 6'2 is shape-optimised to reduce unnecessary foam while retaining enough volume — especially in the tail — to accommodate a broad range of modern shortboard, fish, and groveller designs.

This reduces the need for aggressive foam removal during shaping, resulting in less waste, lower yearly costs and a reduced ecological footprint.

Engineered Fusion.

Our EPS formulation has been fine-tuned for high bead fusion at a carefully optimised density, striking the right balance between weight and strength. This high fusion reduces internal gassing, minimising surface bubbles and pinholes. The result is a blank with improved structural integrity and enhanced compression resistance underfoot.

Proudly designed and manufactured in Australia.

Lighter, Stronger, Cleaner.

⮕ Our EPS density weighs in at 36 kg/m³ — significantly lighter than the 48 kg/m³ average for PU — contributing to a more responsive and buoyant ride.

⮕ EPS blanks are glassed with epoxy resin, which is not only stronger and more durable than polyester, but also emits fewer Volatile Organic Compounds (VOCs) into the ocean as you surf.

⮕ Additionally, EPS provides better energy return under flex — making it the material of choice for both performance and progressive board builders.